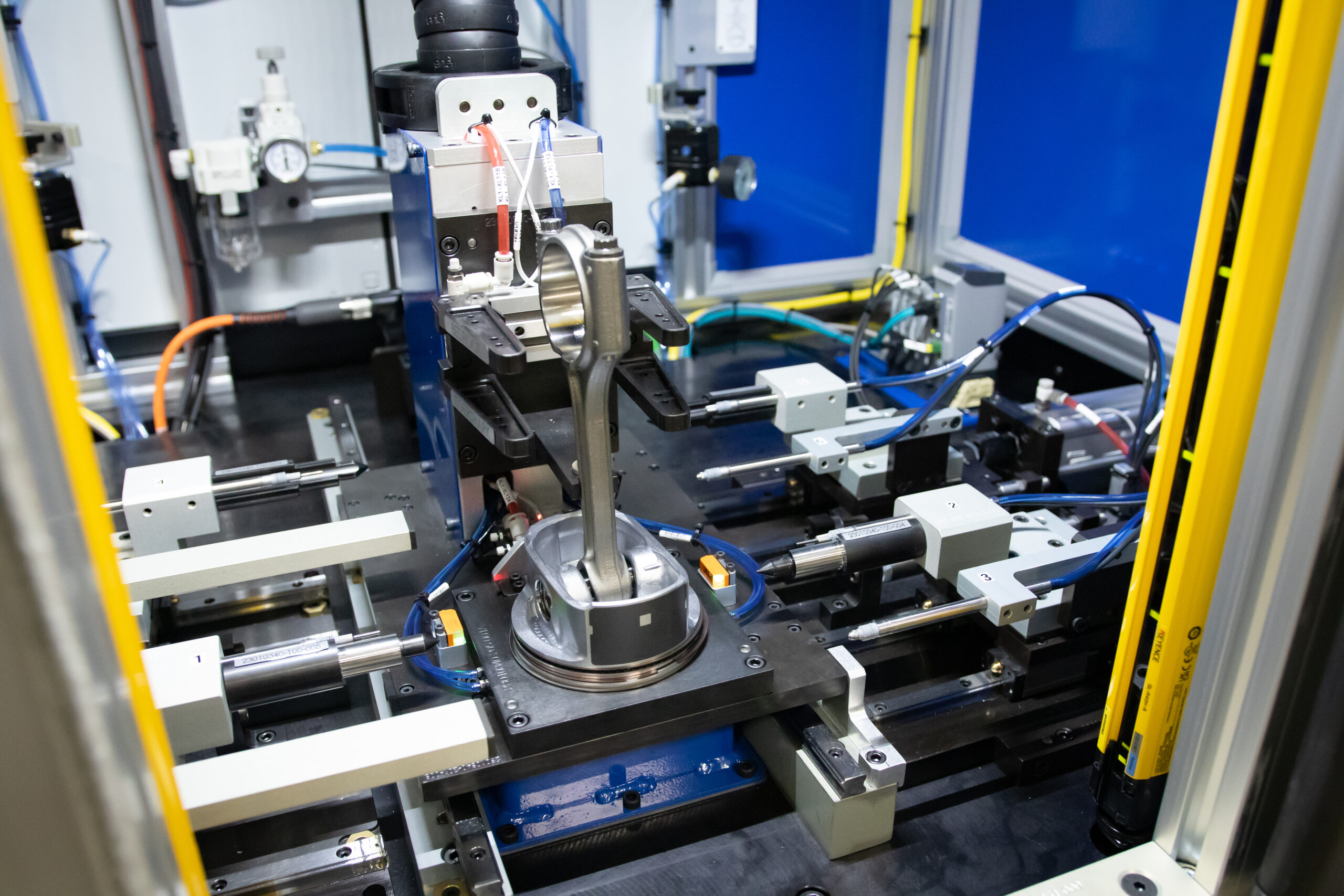

- Weld locations required powered trunnion respot stations

- Material handling to inline operator inspection stations

- Tight part tolerances & part warping due to number of welds

required heavy design engagement with end customer.

Simulation Software Speeds Up Delivery Lead Times on Floorbin Elevator Vibratory Feed Systems

Since 1969, Spectrum Automation has manufactured custom parts feeding and material handling machines. We offer